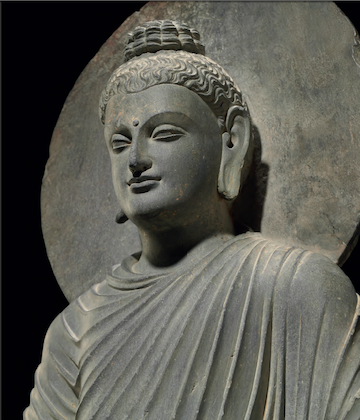

A statue made with stone, usually by carving or assembled to form a visually interesting three-dimensional shape is called stone statue. Since early civilization of human, Stone is being used in architectural sculpture on the outside of buildings and now a days it’s mostly used for making stone sculptures.

We can find evidence of stone sculptures even from the earliest societies indulged in some form of stonework, mostly in India, Egypt, Iran, and Greece etc. But most bewitching and mesmerizing evidences of stone sculptures you can find only in India. Any states or cities in india you may go, you will definitely find evidence of stone monuments across the country. Some of commonly made statues are:

Lord Shiva, Lord Ganesh, Lord Krishna, Lord Jagannath, Sai Baba, Natraj, Chariot wheel, Ashok chakra, Elephants etc.

Soapstone are easy to work and usually used by beginner artist and students for stone craving. Alabaster and softer kinds of serpentine are more durable than soapstone and has long been cherished for its translucence. Then comes the limestone and sandstone, which is two times stronger than Alabaster and commonly used by statue makers as it’s also excellent for carving. Marble stone carving is not that often in India, it’s mostly seen by Greece and European sculptors. It is available in wide variety of colors, like white, black, pink, red and grey etc. The hardest stone which is used for carving is granite. It is the most durable material and most difficult stone to work, that’s why it’s only used by senior artists and highly professional sculptors.

The making of a sculpture starts with choosing the stone. First of all, an artist chooses a stone according to needful weight and dimensions of the statue. The fully dimensional form or figure is created for the first time in the stone itself, as the artist removes material, sketches on the block of stone, and develops the work along the way.

Roughing out

When an artist carves a stone, first he/she starts to remove large unwanted portions. For this task, artist use a point chisel, which is a long, hefty piece of steel with a point at one end and a broad striking surface at the other. A pitching tool may also be used at this early stage; which is a wedge-shaped chisel with a broad, flat edge. The pitching tool is useful for splitting the stone and removing large, unwanted chunks. The sculptor also selects a mallet, which is often a hammer with a broad, barrel-shaped head. The carver places the point of the chisel or the edge of the pitching tool against a selected part of the stone, then swings the mallet at it with a controlled stroke. This is done very carefully to strike the end of the tool accurately; the smallest miscalculation can damage the stone, not to mention the sculptor’s hand. When the mallet connects to the tool, energy is transferred along the tool, shattering the stone. Most sculptors work rhythmically, turning the tool with each blow so that the stone is removed quickly and evenly. This is the “roughing out” stage of the sculpting process.

Refining

Once the general shape of the statue has been determined, the sculptor uses other tools to refine the figure. A toothed chisel or claw chisel has multiple gouging surfaces which create parallel lines in the stone. These tools are generally used to add texture to the figure. An artist might mark out specific lines by using calipers to measure an area of stone to be addressed and marking the removal area with pencil, charcoal or chalk. The stone carver generally uses a shallower stroke at this point in the process.

Final Stages

On this stage the final touch up includes lining & folding of the statue’s cloth, locks of hair and mostly polishing part. Sandpaper has been used as a first step in the polishing process or sand cloth. Emery, a stone that is harder and rougher than the sculpture media, is also used in the finishing process. This abrading, or wearing away, brings out the colour of the stone, reveals patterns in the surface and adds a sheen. Tin and iron oxides are often used to give the stone a highly reflective exterior. Today, modern stone sculptors use diamond abrasives to sand in the final finishing processes. This can be achieved by hand pads in rough to fine abrasives ranging from 36 grit to 3000 grit. Also, diamond pads mounted on water-cooled rotary air or electric sanders speed the finishing process.

Udayagiri caves, Khandagiri caves, Odisha | Kanheri caves | Masroor rock cut temple | Badami cave temple | Bhaja caves | Pancha Rathas, Mahabalipuram | Karla caves | Elephant caves | Ajanta caves | Ellora caves | Konark Temple | Lord Jagannath Temple,Puri are some of the finest example of stone sculpture and monuments and every year millions of visitors come to explore these massive example of Indian culture and mastery of stone art.

The price of statue varies, relative to texture of stone, dimension and weight of stone. As if the same design with equal dimension will differ from each other in terms of texture. Where A Limestone statue of a fixed dimension will cost you 2000 INR, then a granite stone statue of the same dimension may cost you 20,000 INR.

During talk with a statue maker about his earning and profit, he said that they make statue only after someone place an order, so that they don’t need to keep it for so long which will lead them to a loss. He also added profit depends on the volume of order and level of work. If someone need a roughly prepared statue of same dimension it will cost lesser than a same dimension statue with polished and sharp works. A statue of 5 feet, on an average will take 12-15 days to complete with all sharp works and polishing too. Polishing is done to expose the real colour of the statue.

On a final discussion he said a few numbers of workers are left all over the india as there is no skill training available from government level. The skill training provided by private professionals are too high that, no new comer want to come into this field. He also said that, the government neither giving any financial help nor promoting this art to give them a regular income. Sculptors want to sell small statues which can be made with cut piece of big statues, as they have given price for the full stone. They want to use the whole raw material which can give them some extra income. But they didn’t have the market earlier to sell them.

Now a days they are using several e-commerce platform to sell those small statue, which was not feasible before 4-5 years. Mr. Ranganathan also added some specialized platform like Spenowr, who are focused on artist, art and craft only helping them a lot to get extra visibility which they were not getting on other e-commerce platforms.